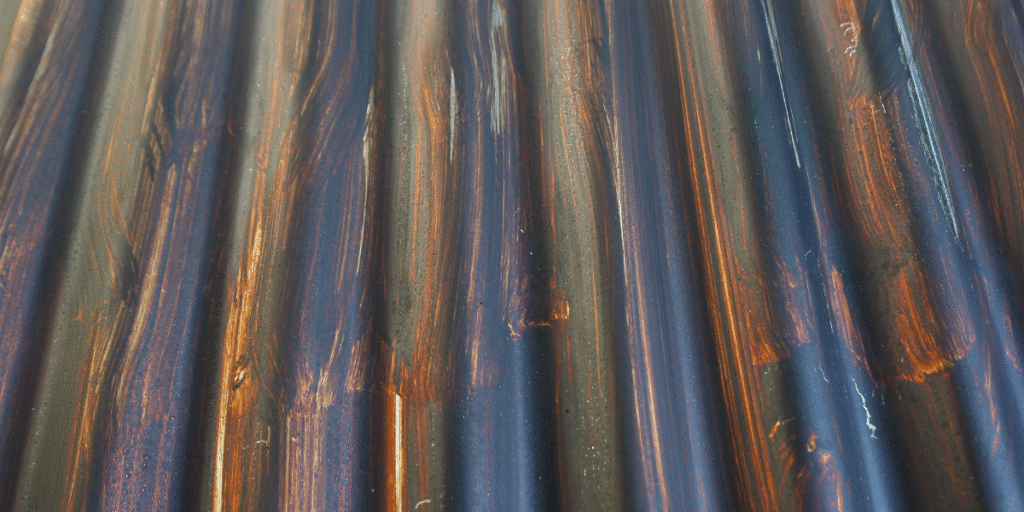

Cut edge corrosion is one of the most common issues seen in metal roofing and cladding systems. It starts when the protective coating applied to steel sheets during manufacturing gets sliced at the edges during installation. These cut edges become exposed to air and moisture, triggering oxidation—and once rust begins, it spreads fast.

Without proper treatment for cut edge corrosion, it cab lead to edge blistering, delamination of the topcoat, and even perforation of the sheet. The impact is more than cosmetic—it can compromise structural integrity and require costly replacement. That’s why early detection and choosing the right paint for cut edge corrosion makes all the difference.

Why Does Cut Edge Corrosion Occur?

Steel sheets are factory-coated to prevent corrosion. However, during onsite cutting and fitting, the edges lose that factory finish. These bare edges are unprotected. Once exposed to oxygen, rain, and pollutants, they start corroding.

The corrosion typically appears first at sheet laps, eaves, and edges—especially where water lingers. Over time, rust travels under the topcoat, lifting and peeling the protective finish. This damages not just the surface but also the substrate, eventually allowing moisture to penetrate the entire structure.

Environmental factors like UV radiation, acid rain, salt spray (especially near the coast), and freeze-thaw cycles accelerate the process. Cut edge corrosion is aggressive—and without professional treatment, it spreads fast.

How to Identify Cut Edge Corrosion

The most common sign of cut edge corrosion is visible rust lines along the sheet edges or where two panels overlap. You may also notice flaking, peeling, or bubbling of the paint near fasteners and joints.

As the corrosion worsens, the metal starts to lose thickness, forming holes or sharp flakes. If left untreated, the problem expands inward and can affect the full surface of the sheet.

Routine visual inspections of the roof or cladding, especially around the lower edges and side laps, help catch the issue early. Industrial facilities, warehouses, and commercial buildings should include edge checks in their scheduled maintenance plans.

Step-by-Step Treatment for Cut Edge Corrosion

Proper repair requires a structured approach. Applying a quick patch or paint won’t last. Each step must be executed with precision to ensure long-term protection.

1. Surface Preparation

Remove all rust, peeling paint, and surface contaminants. Use a wire brush, scraper, or mechanical grinder to clean back to solid metal. Pressure washing with appropriate degreasers can help eliminate trapped dirt or oils.

2. Application of Rust-Inhibiting Primer

Use a high-adhesion primer specifically made to stop corrosion from progressing. This layer acts as the base that prevents further oxidation. Many industrial painting contractors recommend zinc phosphate or epoxy-based primers.

3. Seal the Lap and Edge

After priming, apply a flexible sealant or a fibre-reinforced tape over the lap joint. This step ensures that water, which often pools at overlaps, cannot seep in again.

4. Apply Paint for Cut Edge Corrosion

Once sealed, apply a specialist paint for cut edge corrosion. This paint is engineered to resist weathering, adhere to complex surfaces, and provide lasting protection. Often, a polyurethane or silicone-modified topcoat is used for maximum durability.

This system—clean, prime, seal, and coat—provides a reliable, long-term solution and restores both protection and appearance.

Best Paint for Cut Edge Corrosion Treatment

Using regular metal paint won’t protect against edge failure. A dedicated paint for cut edge corrosion offers enhanced adhesion, UV stability, and flexibility that standard coatings can’t deliver.

Look for coatings that:

- Resist flaking, fading, and UV degradation

- Stay flexible to handle sheet movement

- Bond tightly to sealants or edge tapes

- Are compatible with primers and sealers

Hybrid polyurethane paints and moisture-cure systems are preferred by professionals due to their high-performance finish. Some systems include colour-matched topcoats that restore the sheet’s original appearance.

For best results, always follow the manufacturer’s full system—primer, sealer, and topcoat—designed specifically for treating cut edge corrosion.

Benefits of Early Treatment

Addressing cut edge corrosion early reduces long-term maintenance costs, extends roof life, and protects your building’s appearance. Once corrosion penetrates the sheet, replacement becomes the only option—which is far more expensive than timely repairs.

Other benefits include:

- Improved resistance to water ingress

- Lower risk of insulation damage

- Better thermal efficiency

- Preservation of the original structure

In many cases, clients save up to 60% by treating corrosion early instead of replacing full roof sheets.

Common Industries Affected

Cut edge corrosion is most frequently found in:

- Industrial warehouses with exposed steel roofs

- Agricultural buildings exposed to ammonia or moisture

- Coastal facilities prone to salt spray

- Commercial retail spaces with aging sheet cladding

Each of these environments introduces different threats—chemical, salt, moisture, or organic matter. That’s why tailored coating systems and routine inspections are essential.

Professional vs. DIY Repair

DIY solutions often fail because they don’t treat the full cause. Most DIY kits lack industrial-grade sealants, primers, or paint for cut edge corrosion. Home-grade brushes and rollers can’t match the spray systems used by professionals.

Contractors like USP Coatings use advanced equipment, edge-specific systems, and years of expertise to deliver durable results—on time and on budget.

Final Thoughts

Cut edge corrosion is preventable—but only if treated early and professionally. Exposed steel edges corrode quickly, leading to structural and aesthetic issues if left untreated.

The right treatment method—cleaning, sealing, and using the correct paint for cut edge corrosion—delivers lasting protection and restores building integrity.

USP Coatings provides expert corrosion repair services across the UK, using proven systems designed to stop rust, seal edges, and extend roof life.

FAQs

What is cut edge corrosion?

Cut edge corrosion is the rusting of metal edges exposed during cutting and installation. It occurs when the protective coating stops and the raw edge is left vulnerable to moisture and air.

How to repair cut edge corrosion?

The repair involves rust removal, surface cleaning, application of a primer, sealing the lap joint, and finishing with a corrosion-resistant topcoat.

What is the best paint for cut edge corrosion?

High-performance coatings like polyurethane or hybrid epoxy systems designed for steel edges provide the best protection. These paints resist UV, moisture, and flexing.

What is the best solution for corrosion?

A full system: rust-inhibiting primer, flexible edge sealant, and industrial-grade paint for cut edge corrosion. In severe cases, overcladding may be necessary.