Intumescent paints are a type of fire-protective coating that expands when exposed to extreme heat. This expansion creates a thick, insulating char that shields underlying materials—typically steel, wood, or structural elements—from the rapid rise in temperature during a fire.

Instead of preventing flames entirely, intumescent systems delay heat transfer. This buys critical time for evacuation, rescue, and fire control, helping prevent collapse and irreversible damage. As fire safety regulations grow stricter across the UK, intumescent paints services have become essential for construction, warehousing, and industrial facilities.

How Intumescent Paints Work

When exposed to heat—generally around 200°C to 250°C—intumescent paints react chemically. The coating begins to swell, forming a foam-like char that can grow up to 50 times its original thickness.

This expanded layer acts as insulation. It slows the rate at which the underlying structure heats up, reducing the likelihood of structural failure. The thickened char layer restricts oxygen access, limiting flame spread and giving firefighters more time to respond.

This process is automatic, passive, and doesn’t require electricity or user input. That’s what makes intumescent coating systems so reliable in emergencies.

Where Intumescent Coating Is Applied

Intumescent coating is commonly applied to steel beams, columns, and decking, especially in commercial or industrial buildings where fire risk is high. In these settings, steel loses load-bearing strength rapidly once it reaches 550°C.

These coatings are also used in:

- Warehouses and logistics centers

- Oil and gas facilities

- Hospitals and schools

- Data centers and power plants

- Airports and transportation hubs

In each case, paint coating to protect from fire is not just about safety—it’s about meeting building code requirements and reducing liability.

Types of Intumescent Paints

There are two main types of intumescent paints, and each serves a different purpose based on environment and exposure:

1. Thin-film intumescents

- Water-based, solvent-based, or epoxy-based

- Applied in multiple coats

- Typically used indoors or in controlled environments

- Often covered with a topcoat for aesthetics

2. Thick-film intumescents

- More durable for exterior or high-humidity conditions

- Provide longer protection periods (up to 120 minutes)

- Suitable for offshore or high-risk industrial structures

Choosing between these depends on fire rating requirements, environment, and substrate type. Contractors typically combine intumescent coating with primers and topcoats for maximum durability.

Paint to Protect from Fire vs. Fire-Retardant Paints

There’s a common misunderstanding between intumescent paints and fire-retardant paints. They’re not the same.

Fire-retardant paints delay ignition by releasing flame-dampening gases, but they don’t expand or form a char layer. They’re suitable for light wood, walls, or ceilings but offer limited thermal insulation.

On the other hand, intumescent paints are passive fire protection systems that provide structural protection under load-bearing stress. These are essential for steel frameworks and safety-critical zones.

Understanding the difference ensures that you choose the correct paint to protect from fire, not just one that slows combustion.

Application Process: Why Precision Matters

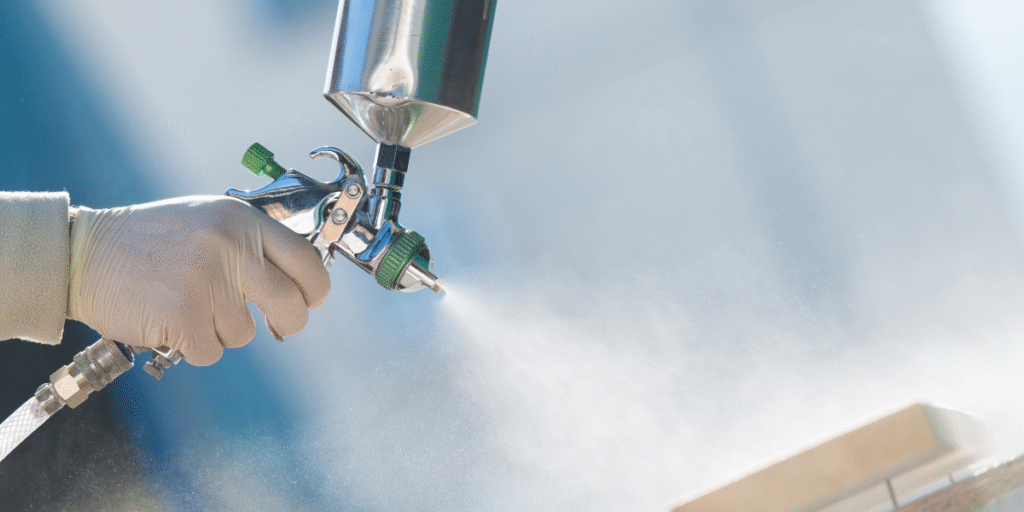

Applying intumescent paints is a specialist task that requires strict surface preparation, correct product layering, and precise curing conditions. Mistakes during application can compromise fire resistance.

A typical process includes:

- Surface prep – Remove dust, grease, and rust

- Primer coat – Improves bonding to substrate

- Intumescent coat – Applied in multiple layers to the required thickness

- Topcoat – Optional, protects from moisture and UV

Thickness is measured with a wet film gauge. Too thin, and it won’t perform. Too thick, and it may crack. Professionals use airless spray or roller systems for accuracy.

Compliance and Fire Rating Standards

In the UK, intumescent coating systems must comply with BS 476 or EN 13381 standards. These ratings specify how long a product can delay fire spread, typically 30, 60, 90, or 120 minutes.

Building owners and developers must ensure that the applied coating meets the required fire resistance period. Documentation, testing, and certification are essential for approval.

Professional contractors like USP Coatings provide product certification, test data, and detailed reports to support compliance.

Advantages of Using Intumescent Paints

While their main benefit is delaying heat damage during fire, intumescent paints offer other practical advantages:

- Maintain the visual appearance of steel structures

- Lightweight compared to fireproof cladding

- Easy to inspect and recoat during maintenance

- Compatible with architectural designs

- Low-impact, passive system—no wiring or alarms needed

They combine aesthetics with safety, making them popular in both exposed interiors and hidden frameworks.

Limitations and Maintenance

Like all protective systems, intumescent coating has its limits. It requires proper environmental conditions during curing. Moisture or improper ventilation can affect adhesion.

Additionally, once cured, the surface must remain intact. Any impact or chipping may expose the substrate and reduce fire resistance. Regular inspections are advised, especially in high-traffic or outdoor areas.

Professional maintenance plans ensure the coating continues to perform over time.

Final Thoughts

Fire safety in structural environments is not optional—it’s essential. Intumescent paints provide an invisible shield that expands during fire to protect what lies beneath. When correctly applied, these systems delay collapse, protect lives, and reduce property damage.

Whether for a warehouse, data center, or office complex, choosing the right paint to protect from fire can be the difference between survival and loss. Intumescent coating offers that peace of mind.

At USP Coatings, expert teams design and apply compliant, high-performance fire protection systems for businesses across the UK. From site evaluation to certification, every project is delivered with accuracy and urgency.

Contact USP Coatings today to book your consultation and ensure your property is fire-safe, future-ready, and legally compliant.

FAQs

What is the difference between intumescent paint and fire-retardant paint?

Intumescent paint expands under heat to form a char that insulates steel. Fire-retardant paint only delays ignition—it doesn’t provide thermal insulation or expansion.

What are the disadvantages of intumescent paint?

It requires precise application, controlled curing conditions, and regular inspection. If damaged, its fire resistance may be reduced.

Where is intumescent paint required?

It’s commonly required in buildings where steel is exposed—warehouses, commercial spaces, industrial plants, and public buildings—to meet fire rating codes.

How expensive is intumescent paint?

Costs vary based on protection duration and substrate size. Intumescent systems are an investment, but far less expensive than structural failure or non-compliance.

How to tell if paint is intumescent?

Intumescent paint is thicker than standard paint and typically labelled with fire resistance ratings. It also requires a primer and, sometimes, a topcoat.