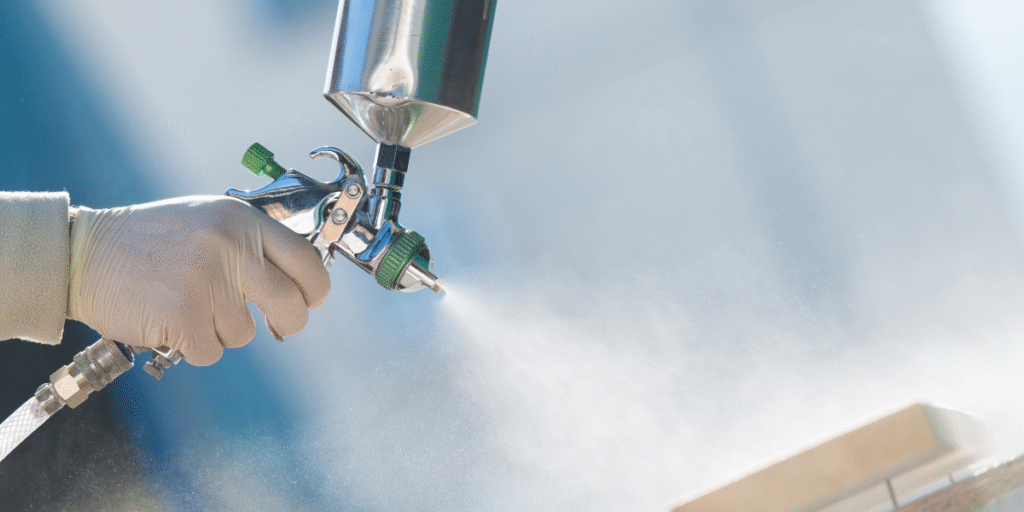

Factory spraying is a fast, cost-effective way to apply paint or coatings in industrial settings. It creates a smooth finish and protects surfaces from damage. Whether it’s metal, wood, or plastic, this method works well and helps industries maintain high standards across the UK.

From warehouses to manufacturing plants, many companies now use this method. But why? Let’s break down the benefits of factory spraying and why you should hire professional services to do it right.

What Is Factory Spraying?

Factory spraying is a method of applying paint or coatings using spray equipment. It covers surfaces evenly and dries quickly. This process is much faster than using brushes or rollers. It is used on doors, cladding, machinery, and more.

In the UK, businesses want quality work done fast. That’s where factory spraying comes in. It gives long-lasting results, especially when done by trained professionals.

USP Coating, for example, uses the latest equipment to deliver consistent and reliable coatings for factories and large spaces. The company helps reduce errors, save time, and make sure your surfaces look good and last longer.

Why Choose Factory Spraying?

Let’s explore the top benefits of factory spraying. These are the reasons why UK industries prefer this method.

1. Clean, Even Finish

The biggest reason companies prefer factory spraying is the smooth finish. It avoids drips, brush lines, or uneven layers. The surface looks clean and professional every time. Plus, you get consistent color throughout.

2. Saves Time on Large Jobs

Factory spraying covers big areas quickly. Unlike hand painting, which takes time and effort, spraying speeds things up. Whether it’s a set of shutters or entire warehouse walls, the work gets done faster.

This time-saving feature means businesses avoid long downtimes. Production continues without major delays. And that’s a big win for your bottom line.

3. Cost-Efficient in the Long Run

Worried about cost? Here’s the good news: Factory spraying reduces waste. Less paint is used compared to other methods. Also, fewer people are needed to complete the job, which cuts labor costs.

While the upfront price might seem higher, the long-term savings are clear. Fewer touch-ups, faster jobs, and less material waste all add up.

4. Long-Lasting Protection

One of the most talked-about benefits of factory spraying is durability. Sprayed coatings resist peeling, cracking, and fading. They also protect against moisture, UV rays, and chemicals.

This protection means you won’t have to repaint or repair surfaces as often. Your investment lasts longer, and your facility stays in great shape.

5. Versatile and Flexible

No matter your surface metal, wood, PVC, or glass factory spraying works. It adapts to all kinds of materials. You can spray doors, cladding, windows, machinery, and even furniture.

Want matte, gloss, or satin? Need a custom color? Factory spraying gives you that flexibility.

What Are the Benefits of Spraying?

People often ask, What are the benefits of spraying? The answer is simple. Spraying ensures faster application, lower labor costs, even coverage, and high-quality results.

Here’s a breakdown:

- Time-saving: Large surfaces can be coated quickly.

- Even results: No streaks, no missed spots.

- Less material waste: Paint is applied efficiently.

- Better protection: Surfaces last longer.

- Wide use: Works for many industries and materials.

These benefits apply to both large factories and smaller business spaces.

Factory Spraying vs. Traditional Painting

Traditional painting methods are still used in some places. However, they don’t offer the same speed or finish. Brushes and rollers leave marks, take more time, and use more paint.

Factory spraying provides clean lines and uniform coverage. It’s also easier to control the thickness of the coat, which helps avoid issues like over-painting or bubbling.

Professional teams that handle factory spraying know how to adjust pressure, distance, and technique to get the best results. That’s why it’s smarter to hire experts instead of doing it yourself.

Professional Factory Spraying Services

Using professional rooftop recoating services or factory spraying services is crucial. Experts understand how to prep surfaces, choose the right coating, and apply it correctly.

Professionals use high-quality equipment and follow safety rules. They also clean and prepare surfaces properly, which helps the paint bond better. That means the coating lasts longer and looks better.

USP Coating is one of the trusted providers in the UK. They offer reliable and efficient factory spraying for commercial and industrial buildings. They also ensure the coating suits your building’s needs.

Choosing a trusted service like USP Coating ensures you get a job done right the first time.

Common Applications of Factory Spraying

Factory spraying can be used on:

- Shopfronts

- Roller shutters

- Cladding

- Ceilings and walls

- Fire doors

- Machinery

- Metal gates and fencing

The versatility of factory spraying is one of its main strengths. It’s not limited to one surface or use.

Maintenance and Aftercare

Factory-sprayed surfaces are low maintenance. They resist dust, stains, and damage. A quick wipe-down is often enough to keep them clean.

Still, regular inspections help. This ensures small cracks or issues are fixed early. Professionals can guide you on how to care for your surfaces properly.

Final Thoughts

If you’re looking to upgrade your factory or commercial space, factory spraying is a smart move. It’s fast, clean, and long-lasting. It also helps your space look sharp and perform better.

When done by professionals, the results speak for themselves. Surfaces stay protected, costs go down, and your space looks brand new.

For expert help in the UK, contact USP Coating today. Their professional services can bring life back to your building while saving time and money.

FAQs

What are the benefits of factory spraying for warehouses?

Factory spraying is a highly efficient method for protecting and upgrading large industrial surfaces, such as warehouse walls, ceilings, and steel structures. It provides a smooth, uniform finish that not only improves the appearance of the space but also enhances durability against dust, moisture, and wear. This technique allows for faster application compared to traditional painting, minimizing downtime and disruption to operations. Over time, the long-lasting coating can reduce the need for frequent repaints, saving both time and maintenance costs.

Can factory spraying be done indoors?

Yes, factory spraying can be safely and effectively carried out indoors when proper precautions are taken. With adequate ventilation, dust control, and the use of protective gear, professionals can apply coatings to indoor areas such as ceilings, machinery, support beams, and walls. Indoor spraying is ideal for refreshing industrial spaces without dismantling equipment or halting operations for extended periods.

How long does the coating last?

When applied by experienced professionals using high-quality materials, factory spray coatings can last 10 years or longer. The lifespan depends on factors like surface preparation, environmental conditions, and the type of coating used. Regular maintenance, such as cleaning and inspections, can help extend the life of the coating and maintain its protective and aesthetic qualities.

What are the benefits of spraying compared to brushing?

Spraying offers several advantages over traditional brush painting. It delivers more even coverage, especially over textured or hard-to-reach surfaces, and typically uses less paint due to its efficient application method. Spraying is also significantly faster, reducing labor time. Unlike brushing, which can leave visible streaks or brush marks, spraying provides a smooth, professional-looking finish that enhances the overall appearance of industrial spaces.

Why hire professionals for factory spraying?

Hiring professionals ensures the job is done safely, efficiently, and to a high standard. Trained factory sprayers understand how to properly prepare surfaces, choose the right coating products, and apply them with precision. They also follow industry safety protocols and environmental regulations. The result is a longer-lasting, high-quality finish that resists wear and adds value to your facility.