Thinking What Is an Intumescent Coating? Well, An intumescent coating is a special type of paint. When exposed to heat, it expands and forms a thick, charred layer. This layer slows the spread of fire. The coating can protect steel, wood, and other surfaces. It’s often used in public buildings, offices, and warehouses. The goal is simple: buy time in case of a fire. These extra minutes can save lives and reduce damage.

What Is an Intumescent Coating And Why They Are Important?

When fires break out, every second counts. Intumescent coatings slow heat transfer. They help structural materials hold up longer in extreme temperatures.

Without these coatings, steel can bend or collapse. Wood can ignite and burn quickly. Adding intumescent coating for wood or steel creates a barrier against heat and flames.

This is why professionals across industries trust it. It’s one of the most effective ways to protect both lives and property.

Intumescent Coating for Wood

Wood is widely used in homes and buildings. But it’s naturally flammable. That’s where intumescent coating for wood comes in.

This coating creates a protective char when exposed to heat. It prevents the wood from catching fire right away. It also slows the rate at which flames can spread.

Here’s why property owners and contractors love it:

- Easy to apply with a spray or brush.

- Keeps the wood looking natural.

- Meets safety standards for fire protection.

Whether it’s beams, doors, or panels, this coating is a smart upgrade for fire safety.

Intumescent Coating for Steel

Steel structures are strong but only up to a point. At 550°C (1022°F), steel can lose 50% of its strength. That’s dangerous in a fire.

Using intumescent coating for steel gives you more time. As the fire heats up, the coating expands. It creates a foam-like layer that insulates the steel.

This helps the structure stay intact longer. Firefighters and occupants get more time to respond.

Professionals often apply this in:

- Office buildings

- Factories

- Warehouses

- Shopping centers

At USP Coating, we apply intumescent coating for steel with care. Our team checks thickness and cures the surface correctly for best results.

Shop Front Respraying: Fire Protection With Style

Shopfront respraying does more than give your storefront a fresh look. It also allows professionals to apply fire-resistant coatings. This protects your property, employees, and customers.

When we spray shop fronts, we often use intumescent coatings. These coatings add an extra layer of safety. At USP Coating, our expert team makes sure your respraying job looks great and meets fire safety standards.

The next time you need a shop front respraying, consider it a chance to increase safety, too.

The Application Process

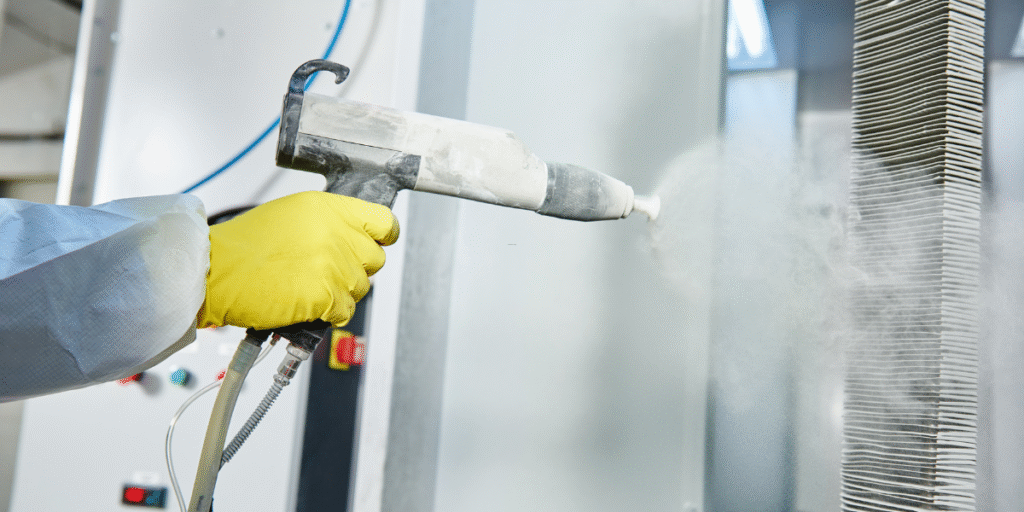

You must apply the intumescent coating correctly for it to work. Here’s a simple overview of the steps involved:

- Surface Prep: Clean the surface and remove dust or oil.

- Priming: Apply a primer to improve bonding.

- Spraying: Use airless spray for even coating.

- Drying and Curing: Allow proper drying time to ensure performance.

- Inspection: Measure thickness to confirm fire rating.

For shop front respraying projects, we often combine this with color or finish updates. That way, you improve safety without changing the look of your property.

Benefits of Intumescent Coatings

There are many reasons to choose this type of fireproofing. Here are the most important ones:

- Fire Resistance: Buys valuable time in a fire emergency.

- Visual Appeal: Can be tinted or covered with topcoat.

- Cost-Effective: Less expensive than replacing damaged structures.

- Lightweight: Doesn’t add extra load to structures.

- Versatile: Works on wood, steel, and other materials.

When combined with shop front respraying, the result is both beautiful and fire safe.

Who Needs Intumescent Coating?

If you own or manage a building, chances are you need this type of protection. Common users include:

- Landlords of commercial buildings

- Homebuilders and developers

- Business owners upgrading storefronts

- Construction companies

- Industrial site managers

Don’t wait until after a fire to take action. Intumescent coatings are a smart investment upfront.

Why Choose Professional Intumescent Coating Services?

Applying intumescent coating isn’t just about brushing on paint. It takes experience, tools, and strict safety checks. That’s where professional intumescent coating services come in.

Experts like USP Coating ensure the job meets both fire safety standards and your project’s needs. They use certified materials, test coating thickness, and follow all safety rules. This guarantees strong fire protection for both steel and wood surfaces.

Even more, a professional team inspects surface conditions before starting. They remove rust, dust, or old paint so the coating sticks properly. After applying the base layer, they check for coverage and then add a weatherproof topcoat when needed—especially for outdoor jobs.

When you hire skilled professionals, you save time and avoid future problems. DIY work often misses hidden damage or skips key steps. But with trained experts, the result is cleaner, safer, and lasts much longer.

USP Coating also offers shop front respraying, helping clients refresh and protect their commercial spaces while meeting all safety requirements. Their team finishes projects on time, within budget, and with little disruption to your business.

So, whether you need fireproofing or want to upgrade your storefront, professional help makes all the difference.

Why Choose USP Coating?

At USP Coating, we understand the need for fire safety and good design. Our experts apply intumescent coatings with care and precision.

Whether you’re focused on shop front respraying or full structural protection, we’ve got you covered. Our team follows strict quality standards from prep to finish.

We’ve helped countless property owners add beauty and safety in one go.

USP Coating only uses high-quality, industry-approved products. We don’t cut corners. We also provide guidance on building regulations and compliance needs.

Final Thoughts on

Intumescent coatings are a smart, simple way to protect wood and steel from fire. They’re especially valuable when paired with services like shop front respraying.

They don’t meet fire safety standards; they exceed them. USP Coating provides reliable intumescent coating for both wood and steel. You can trust our professional service.

Contact us today to get started on your next project.

Frequently Asked Questions

- How often should intumescent coatings be inspected?

Intumescent coatings should be inspected at least once every 12 months. Regular checks help spot any damage, such as cracking or peeling. If the coating is damaged, it might not work well in a fire. So, a professional should reapply it quickly.

- Can intumescent coatings be used outdoors?

Yes, they can be used outdoors, but they require a protective weatherproof topcoat to last. Without this top layer, rain, UV rays, and temperature changes can harm the coating. Proper planning and expert application are key to outdoor use.

- Does intumescent coating affect the color of surfaces?

Intumescent coatings can have a slight tint or matte finish. But, most projects include a final decorative topcoat or paint. This keeps your surface looking clean and stylish while maintaining fire resistance.

- How thick should the coating be?

The thickness of an intumescent coating depends on how much fire protection you need. It can range from a few hundred microns to several millimeters. USP Coating uses precise tools. They measure and apply the right thickness.

- Is intumescent coating safe for the environment?

Most modern intumescent coatings are water-based. They also have low levels of VOCs, or volatile organic compounds. This makes them safer for indoor use and better for the environment. Always choose certified, eco-friendly products and consult experts for safe application.